Transistor 101

The transistor is widely regarded as one of the most important inventions of the 20th century, and is the key enabling technology in virtually every electronic device today. From smartphones to satellites, without transistors most of today's modern technology would not exist.

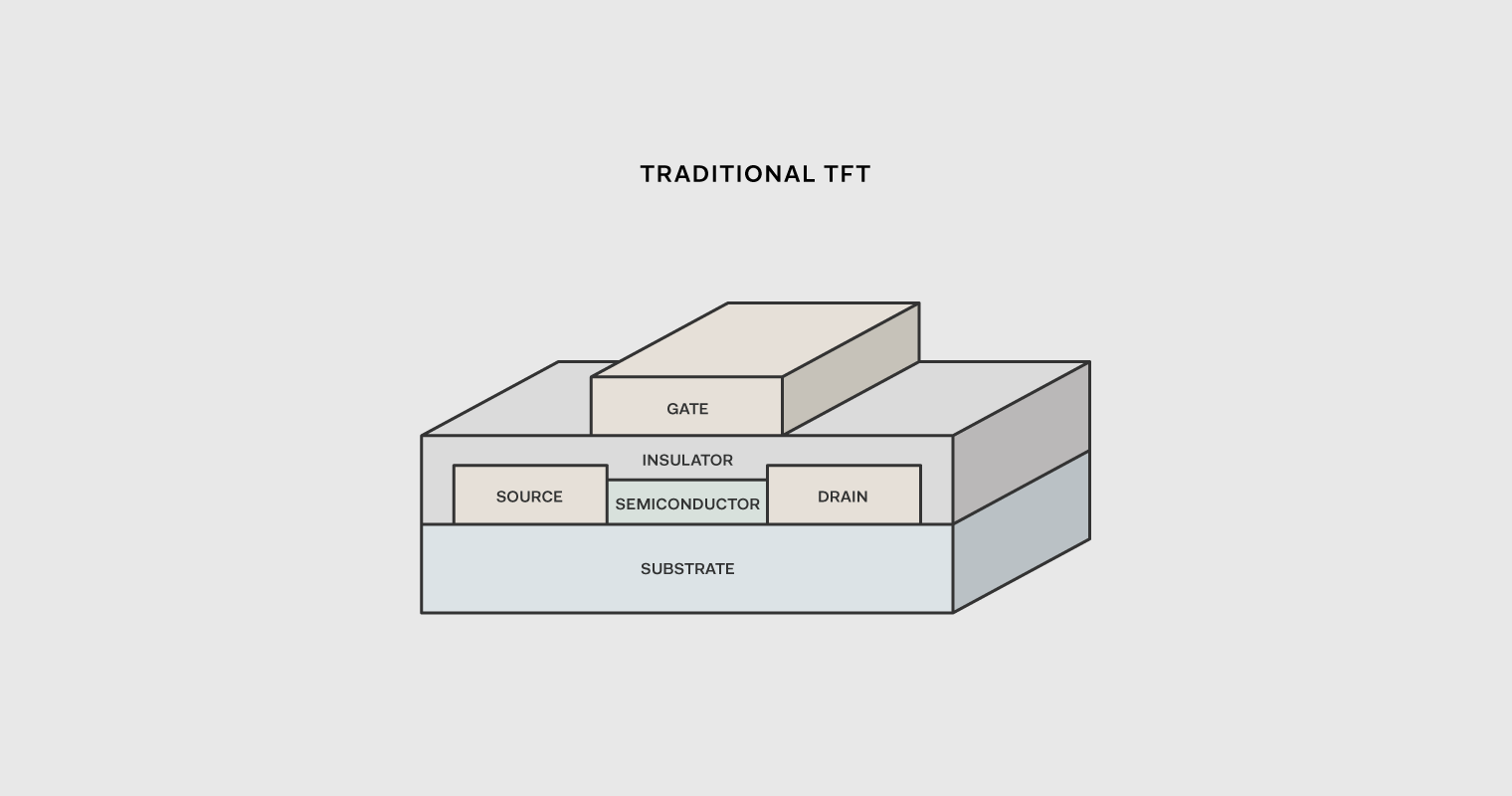

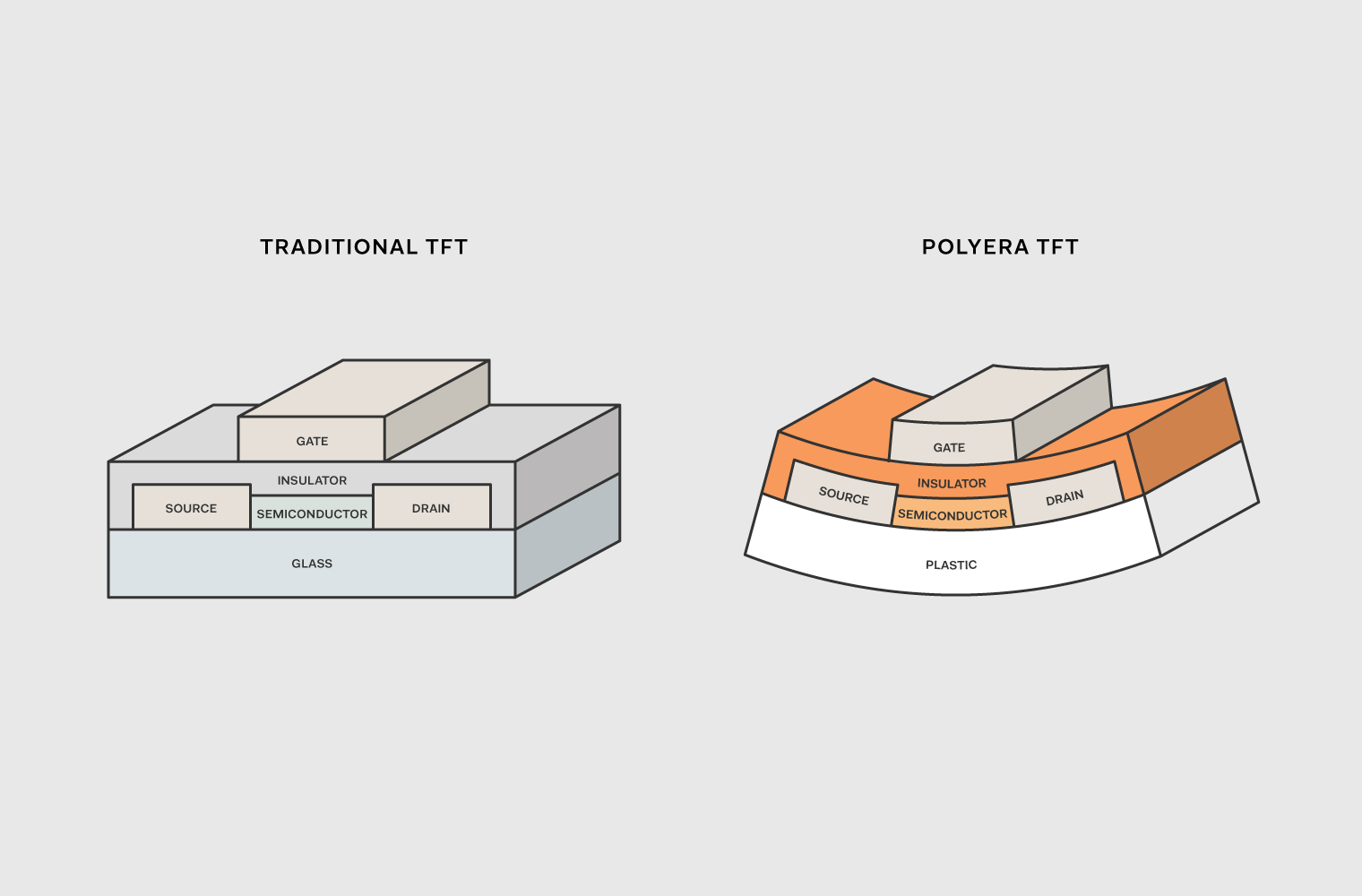

One of the most common types of transistors is known as the Thin-Film Field Effect Transistor, or TFT for short, and looks like this:

A TFT acts like an electronic valve: when a voltage is applied to the gate, the semiconductor material is switched “on”, allowing current to flow from the source to the drain:

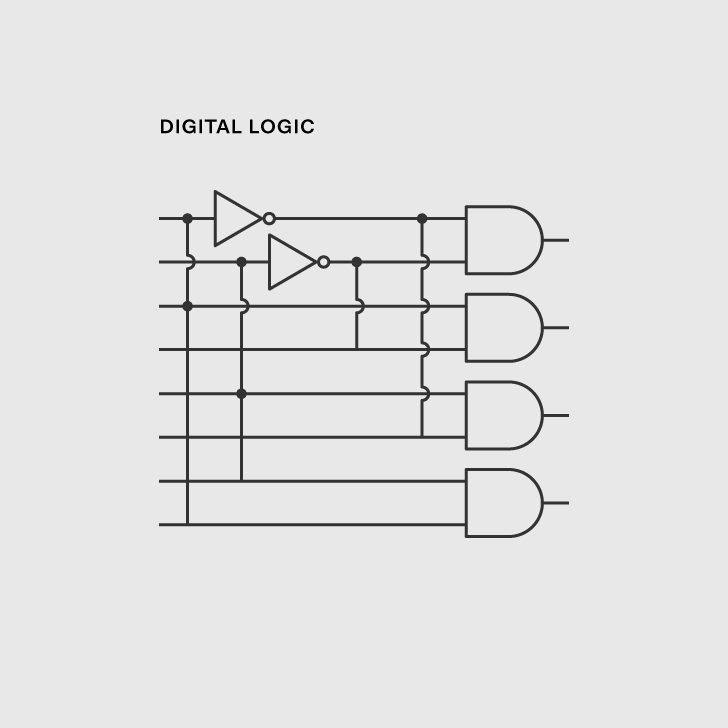

TFTs can be used in many ways, but two of the most common are display backplanes and digital logic.

Displays

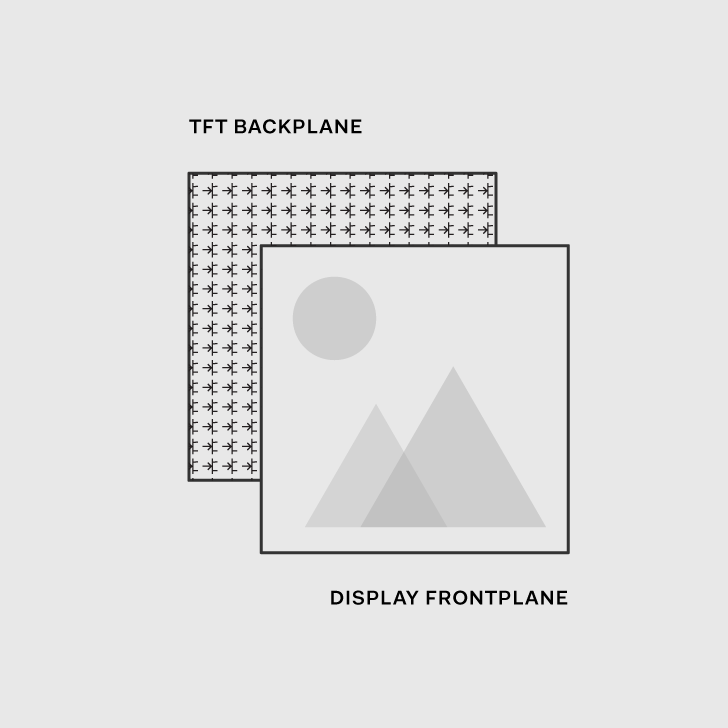

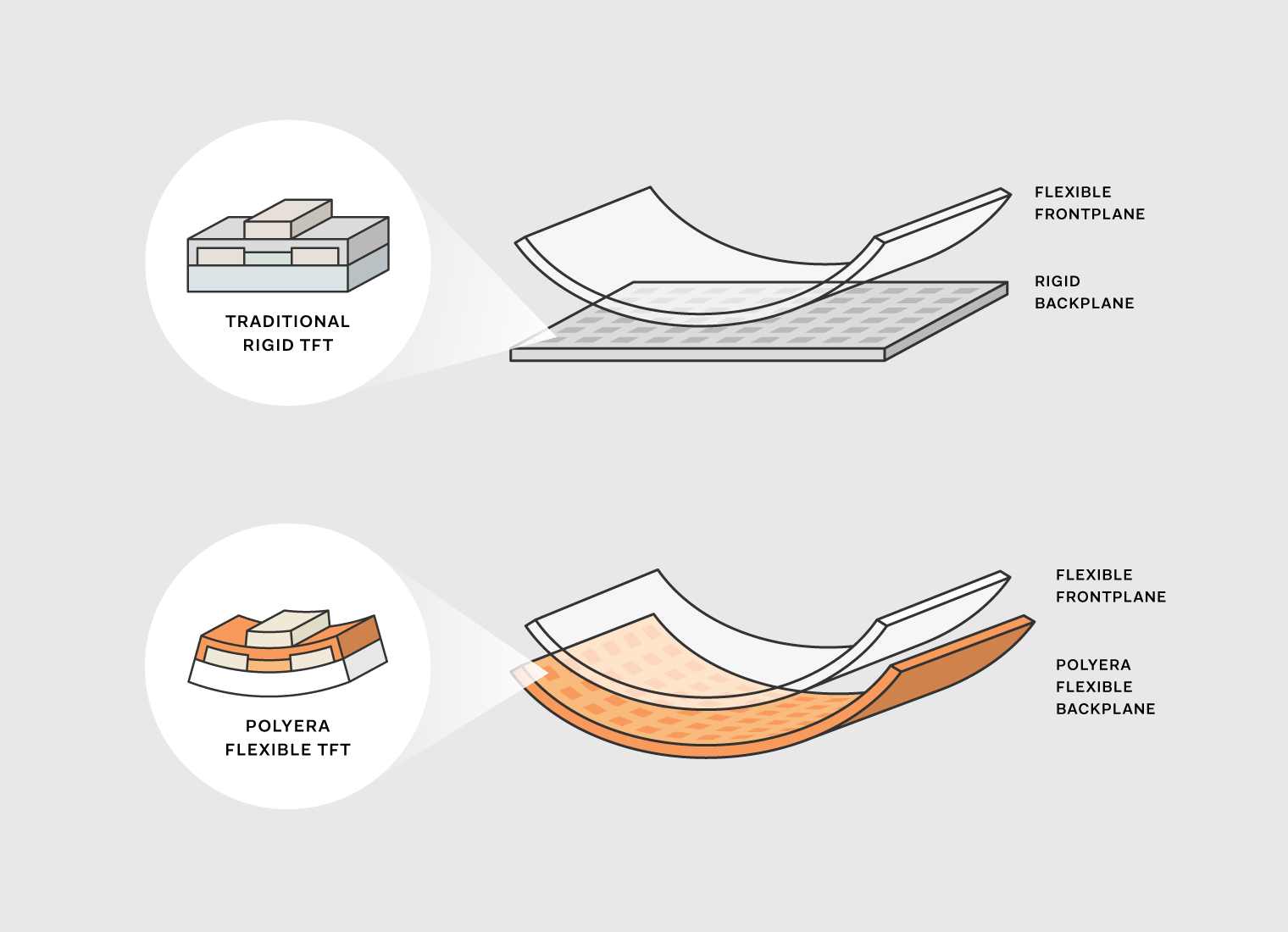

At a basic level, a display is made up of two parts: a frontplane, the layer that makes the image you see, and a backplane, an array of TFTs that control which pixels in the frontplane turn on and off. Most of the time, when you hear about displays, you hear about the frontplane technology–e.g. LCD, OLED, e-Paper, etc.–because that's the part you see.

If you want to make a display flexible, however, you need both the frontplane and the backplane to be flexible, and you need both to be durable enough to be used in the real world. OLED and e-Paper frontplane technologies already have the required levels of flexibility and durability, however, the backplane has previously been a constraint.

With Polyera Flexible TFTs, however, the backplane can also be made flexible, making the full display flexible:

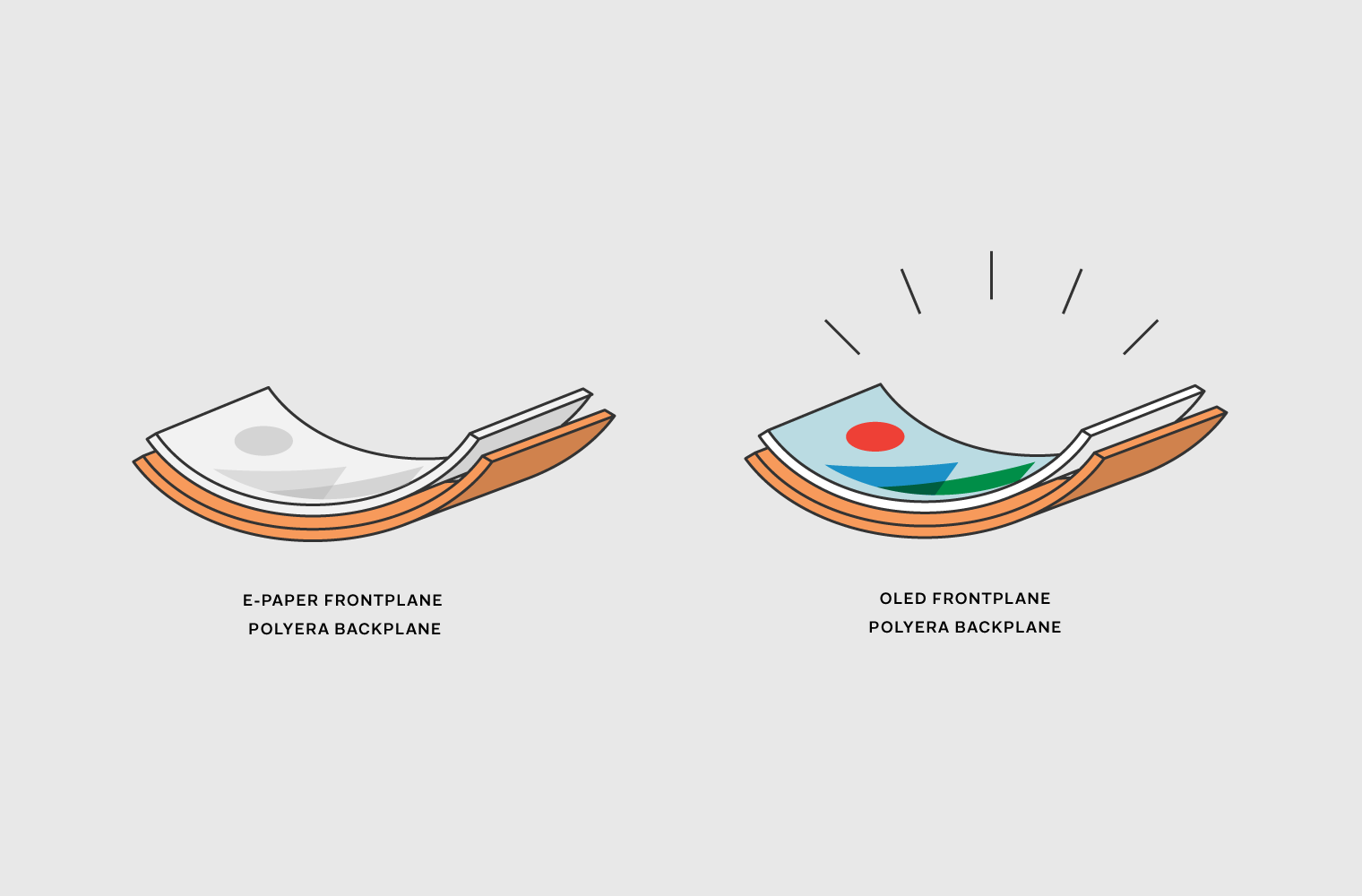

This also means that Polyera Flexible TFTs can be used to make both e-Paper and OLED displays flexible:

Flexible TFTs: A Material Difference

Polyera Flexible TFTs are made from proprietary materials developed by Polyera. These materials have electrical properties similar to the materials traditionally used in TFTs, but with novel physical properties, including true flexibility.

Most attempts to make flexible displays have relied on depositing traditional electronic materials, such as silicon, on plastic substrates. This approach allows the creation of products with displays in a fixed curve, but the brittleness of these electronics layers makes them unsuitable for products which are dynamically flexible. Polyera’s proprietary materials, by contrast, are flexible and robust, enabling the creation of products with true, dynamically-flexible displays.

Enabling Manufacturing at Scale, Today

There have been other attempts to use novel materials that are more robust than traditional silicon, but these have required either building entirely new display fabrication plants, or significant investment to modify existing ones. Polyera’s materials, however, can be easily used in existing display fabrication plants. This means that display manufacturers can quickly start producing flexible displays with their existing processes and equipment–no new fabs need to be built, and existing production capacity can be used without costly modifications.

But flexible displays are just the beginning. Polyera Flexible TFT technology also enables the manufacturing of TFTs using inkjet and roll-to-roll printing processes. This means you can literally print circuitry. This also means faster manufacturing and lower costs, allowing you to put electronics places you never could before: intelligence could literally be printed onto packaging.

A Revolution in Transistor Technology

Polyera’s Flexible TFTs are the culmination of over 10 years of deep chemistry and physics R&D, and form the core of Polyera Digital Fabric Technology™. Whether enabling displays or logic, and whether used as a drop-in solution to traditional display manufacturing plants or using novel techniques like printing, Polyera Flexible TFTs represent a revolution in transistor technology that will enable the next generation of electronics.